Technology

Electrodeionization modules are built using multiple layers of ion exchange membranes with the space between each membrane filled with ion exchange resin. The ion-exchange membranes are stacked up by alternating layers between those that pass only anions (anion exchange membrane) and those that pass only cations (cation exchange membrane). The layers are placed in between two electrodes and the stack connected to a power supply to create the electrical driving force for continuous deionization.

As feedwater moves into the stack in the dilute channel, the residual salts and ionizable aqueous impurities (such as carbon dioxide, silica, ammonia and boron) first attach to the ion exchange resin. The direct current electrical field between the electrodes moves anions through the anion exchange membrane toward the anode and into the next layer of ion exchange resin where it is trapped by the alternating use of the cation exchange membrane in what is called the concentrate channel. Conversely, the direct current electrical field moves cations through the cation exchange membrane in the opposite direction toward the cathode and where it is trapped again in a resin-filled concentrate channel by alternating use of anion exchange membrane. As the water moves through the stack in the dilute channel, impurities continue to be removed for the production of ultrapure or high purity water.

As feedwater moves into the stack in the dilute channel, the residual salts and ionizable aqueous impurities (such as carbon dioxide, silica, ammonia and boron) first attach to the ion exchange resin. The direct current electrical field between the electrodes moves anions through the anion exchange membrane toward the anode and into the next layer of ion exchange resin where it is trapped by the alternating use of the cation exchange membrane in what is called the concentrate channel. Conversely, the direct current electrical field moves cations through the cation exchange membrane in the opposite direction toward the cathode and where it is trapped again in a resin-filled concentrate channel by alternating use of anion exchange membrane. As the water moves through the stack in the dilute channel, impurities continue to be removed for the production of ultrapure or high purity water.

Electrodeionization is a critical part of the evolution of demineralization systems from several sequential ion exchange vessels and toward membrane-based systems. In such a flow sheet with reverse osmosis, EDI systems can replace mixed-bed ion exchange systems and provide reliable production of ultrapure or high purity water. Additionally:

- EDI requires no regeneration chemicals which simplifies environmental, health and safety concerns and reduces chemical costs

- EDI operates continuously which minimizes risk of breakthrough from exhausted resin and simplifies operations by eliminating the need to take a system offline for regeneration

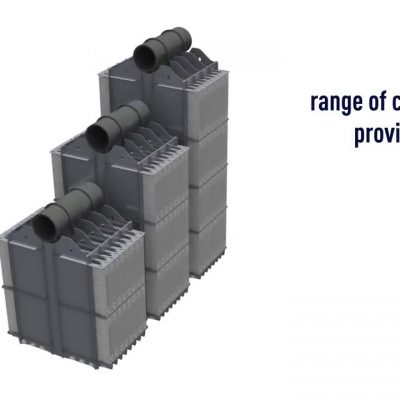

- EDI reduces facility requirements by having a smaller footprint and lower height requirement than ion exchange, particularly when including supporting equipment such as chemical dosing systems

- EDI has no hazardous wastewater discharge and wastes can be easily recycled without the neutralization systems needed for ion exchange